Providien manufactures and supplies a full range of comprehensive and innovative engineering support for designing, testing, and manufacturing a wide range of electromechanically assembled and mechanical assembly products.

Our team will save you time and money on your next custom medical device assembly needs. From solid-model design to bearing life calculations using the latest COBRA software we work to produce world-class products on-time and on budget.

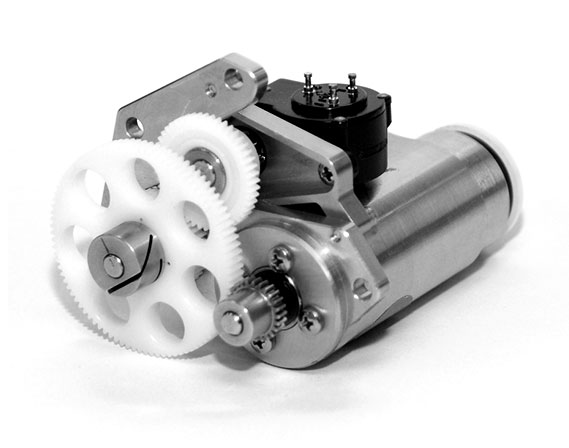

Electro-mechanical Assembly

Electro-mechanics combines electrical and mechanical processes and procedures gathered from electrical engineering and mechanical engineering drafted plans.

Electromechanical Assembly is the process of putting together the equipment that controls the flow of electrical current needed to operate everyday mechanical equipment such as pacemakers, cell phones, and thermostats.

Providien is a leading manufacturer of clinically superior medical devices that depend on electromechanical functions to ensure unsurpassed reliability and performance.

Providien is ISO 9001:2008 and ISO 13485 certified and is a supplier to FDA-critical and PPAP standards.

What is ISO 13485 Certified?

ISO 13485 is an International Organization for Standardization which represents and established the requirements for comprehensive quality management for the design and manufacture of medical devices.

ISO 13485 is now considered to be inline standard and a requirement for medical devices. Certification via ISO 13485 standards ensures a company is committed to top-quality production and is using the most up-to-date standards and specifications as they manufacture their products.

Mechanical assembly

While electromechanical assembly involves adding the electronic elements of that product to the process of putting together the different parts, that make up a tool or product, mechanical assembly is the same process with the absence of the electronic parts. Providien specializes in manufacturing devices that use both of these technologies.

Manufacturing engineers create assembly drawings

Detailed process instructions document production from manufacturing to final assembly and testing

Mechanical and electro-mechanical assembly facility in Los Angeles County, California.

Providien will process your Bills of Materials from 2 to 200 line items, from concept to final assembly, on one purchase order, reducing the need for multiple suppliers. We offer an all-inclusive process that eliminates the customers’ costs associated with the incoming inspection of each individual component, creating a competitive, cost-effective process.

FDA Critical and PPAP Standards

PPAP (Production Part Approval Process) is a standardized process in the manufacturing industry that helps implement the highest levels of communication and production approval processes throughout the journey from design to completion of a product. PPAP helps to ascertain that the manufacturer and the client are on the same page when it comes to the specifications needed to create the product that the client is seeking, in the highest quality form.

Similarly, the Food and Drug Administration (FDA) has quality standards that it promotes and encourages to medical device manufacturing facilities so that these devices are manufactured to be safe as well as effective. Providien adheres to both the FDA Critical and the PPAP standards in order to provide top-of-the-line devices.

The Highest Quality Products

Providien has expertise with Class II and Class III electromechanical assembly in finished medical devices. In layman’s terms, this means that Providien has the experience and expertise to manufacture quality devices that require even the highest level of regulatory control. Our experienced team has been manufacturing these types of class II and III devices for over 20 years in our state of the art manufacturing and assembly facility in Tijuana, Mexico.

Let the Providien team’s extensive experience and commitment to superior quality provide you with the peace of mind and confidence needed for the assembly of your complex medical devices. Our robust validation and transfer protocols ensure a smooth launch for your electromechanical assembly product and finished device.

Providien is an established manufacturer that focuses on improving product quality and reliability while reducing time-to-market and costs.