Providien’s precision machining facility is both ISO 9001 and ISO 13485 certified and specializes in tight-tolerance machining, which separates us from other contract manufacturers. We gained this world-class capability as a function of our precision bearing expertise.

Our machined parts have historically needed to meet the tolerance requirements of our bearings and our mechanical assembly in support of the medical device and aerospace industries.

Providien has implemented a manufacturing and quality system devoted to meeting the tightest of our customers’ specifications. Every member of our Manufacturing and Quality Control teams is dedicated to our customers’ requirements. We examine every detail of the parts we manufacture and regularly build fixtures and add equipment to our Quality Control department to fulfill inspection requirements.

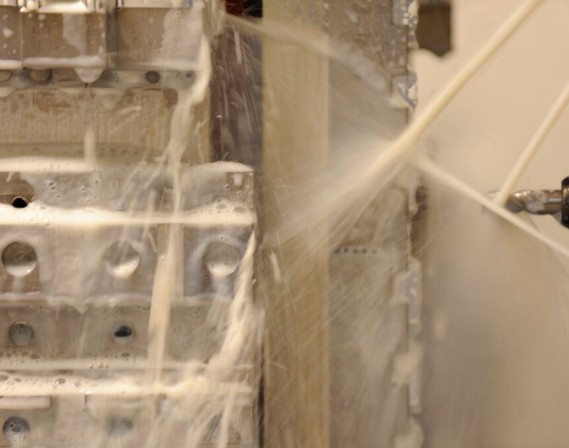

Providien has invested in state-of-the-art equipment, including multi-axis CNC lathes, Swiss screw machines, multi-axis horizontal and vertical mills with pallet changers and CMM measuring machines. Providien’s investment in equipment, processes and people allow us to control costs, optimize productivity levels and improve turnaround time.

Additional Machining Capabilities

- Surface Grinding

- Tumble Deburring

- Ultrasonic Cleaning

- Citric Passivation

Contact us to view a complete equipment list and to discuss our vertically integrated bearing, precision machining and mechanical assembly expertise.