What is Insert Molding?

Insert Molding (or “insert molding”) is the process of molding plastic around an insert that is placed into the injection mold.

This insert is typically a metal insert but may also be a made of plastic. The insert is placed into the mold by one of two methods:

1. By robotic insert loading.

2. By manual loading.

Both of the above methods use a fixture to insert the part to ensure the accuracy of placement.

Because gravity aids in the insert molding process, vertical injection molding presses are often utilized. However, horizontal injection molding presses may also be used.

Insert Machining

In many cases, Providien Machining & Metals can machine the insert as well. This serves to reduce the cost for our customers while ensuring quality at our ISO 13485 certified facilities.

The image below is a good example of an insert molded part. In this case, the metal part is the insert and the purple plastic handle is molded around the insert.

Benefits of Insert Molding Include:

- 1. More robust part when compared to two independently molded parts which are assembled in a secondary assembly process.

- 2. Elimination of glue, which can be a high failure mode for these types of parts.

- 3. Lower total assembled part cost.

4. Less part to part variability.

What is OverMolding?

The overmolding process is very similar to insert molding. In this case, one piece of plastic is injection molded and then another piece of plastic is molded over it.

The materials may be similar or different and either result in a mechanical or chemical bond. This may differ from insert molding in which case a mechanical bond is typically created.

It is also common to have a two-shot injection molding process to produce the overmolded part.

This process typically includes rotary platen or movable core with two injection units and two runner systems allowing the overmolded to be produced in one press.

In many cases, the substrate (first shot) is PC/ABS, PP or ABS with the second shot being a TPE or TPU.

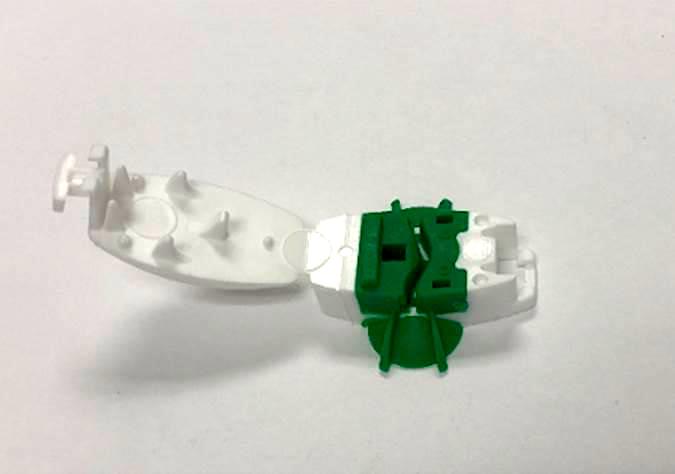

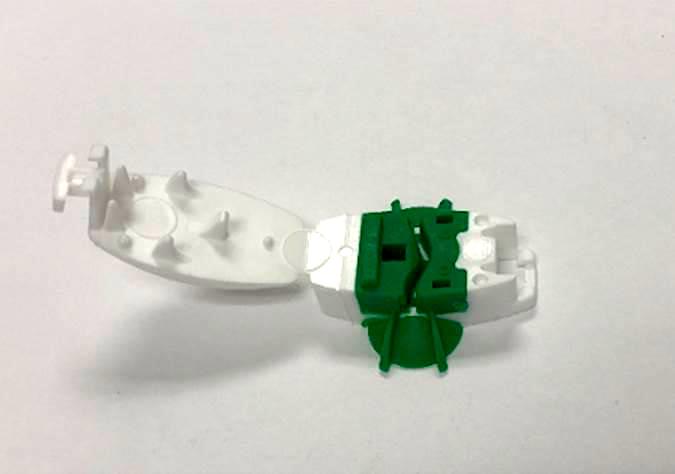

The below part is a good example of an overmolded part, with the substrate (white portion) being a PP with the overmolded (green portion) being TPE.

Benefits of Overmolding Include:

- 1. More robust part as compared to two independently molded parts and assembled in a secondary assembly process.

- 2. Elimination of glue, which can be a high failure mode for these types of parts.

- 3. Lower total assembled part cost.

4. Less part to part variability.

Providien has vast experience in both insert and overmolding. Our engineering can assist you in making this important decision.