Providien is a world-leading thermoformer of highly aesthetic, complex medical device enclosures and products. Providien specializes in manufacturing large, multi-part enclosures for the medical device industry. Providien is proud to maintain a relentless focus on achieving the highest quality standards of plastic pressure forming, twin sheet forming, thin gauge packaging, vacuum forming, and CNC machined aluminum tooling. Providien utilizes an innovative approach to meet the demanding, close-tolerance design requirements of our customers. Providien focuses on pressure forming to achieve these highly cosmetic medical device covers.

The best characteristics of pressure formed parts include:

- tight tolerances,

- crisp detail,

- formed-in texture,

- custom color without paint,

- and formed-in threaded inserts to ensure repeatability.

Pressure formed parts have aesthetics that are on the same level as injection molded parts at a fraction of the tooling cost.

Providien is also a leader and pioneer with twin sheet pressure forming. Twin sheet thermoforming has significant advantages over competitive plastic processes and single-walled parts.

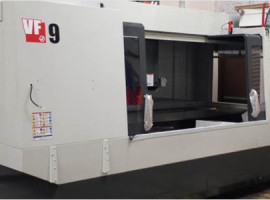

Twin sheet parts can remove the need for sheet metal structural backing while providing cosmetic and controlled surfaces on both sides. Doors and lids can be ideal candidates for this process.![]()