Providien has been a world-leading thermoformer of highly aesthetic, complex medical device enclosures and other plastic products for over 40 years. These decades of experience have helped to make Providien a trusted and competent source for your company’s twin sheet thermoforming needs.

What is Twin Sheet Thermoforming?

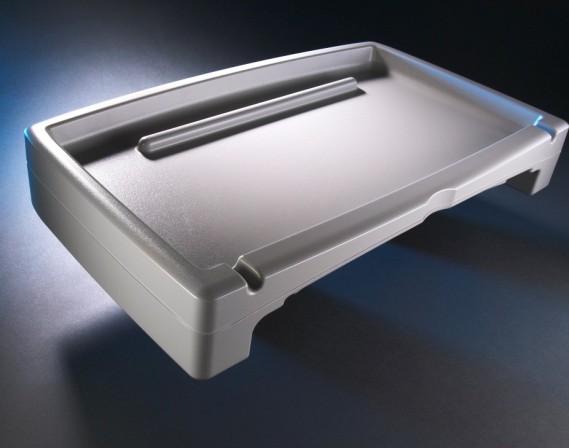

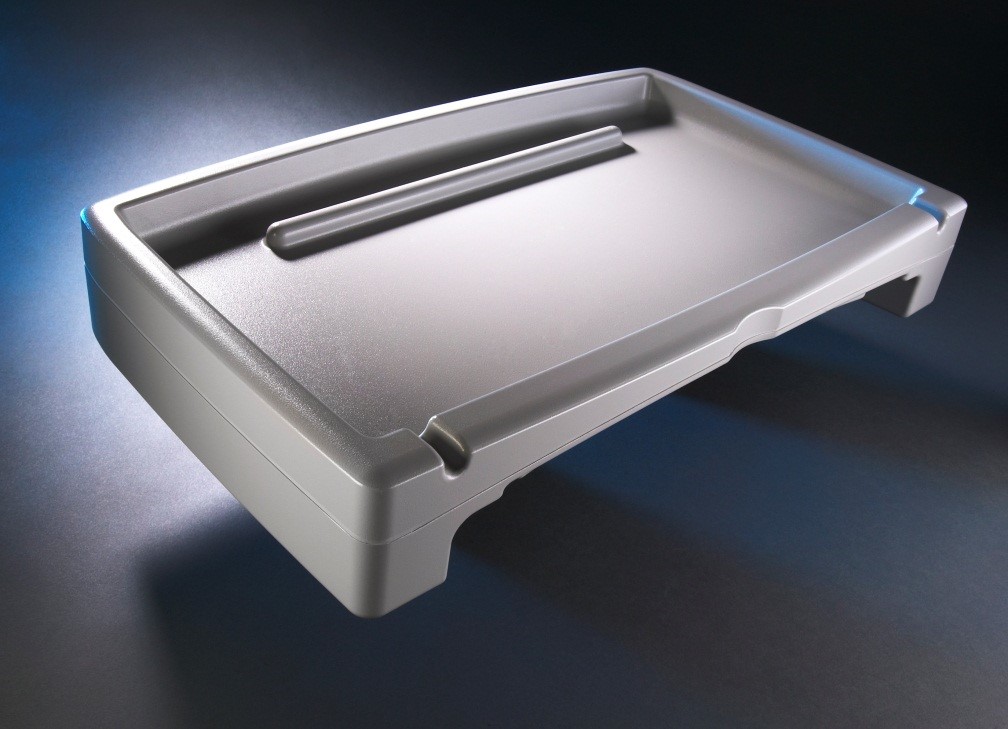

In the twin sheet thermoforming process, two separate sheets of material are heated simultaneously. One sheet is drawn into a top tool and the other sheet is drawn into a bottom tool using a vacuum process. The tools are then brought together and pinched around the perimeter of the part. Forced air is applied between the sheets, pressing each sheet into its respective tool resulting in a hollow part that is structurally rigid and cosmetic on both sides.

Parts that need to be controlled and/or cosmetic on both sides are ideal candidates for this process. Doors, panels, and lids are great examples of these types of parts. An additional benefit of is that they dampen noise and due to the trapped air cavity; can act as a thermal insulator.

Advantages of Twin Sheet Thermoforming

Twin sheet thermoforming has significant advantages over competitive plastic processes and single-walled parts.

Some of these advantages are as follows: